Anyone who has worked in a container terminal knows this situation all too well:

A vessel planner needs a specific container for loading. The Terminal Operating System (TOS) shows it sitting neatly in Block A, Bay 12, Row 5, Tier 3. The RTG operator arrives… only to find nothing there – or worse, an entirely different container.

Now equipment begins searching the yard, the vessel schedule slips, and the team scrambles to locate the box.

These discrepancies happen far more often than most terminals admit – and the costs add up quickly.

Capturing Every Box ID with Spreader OCR

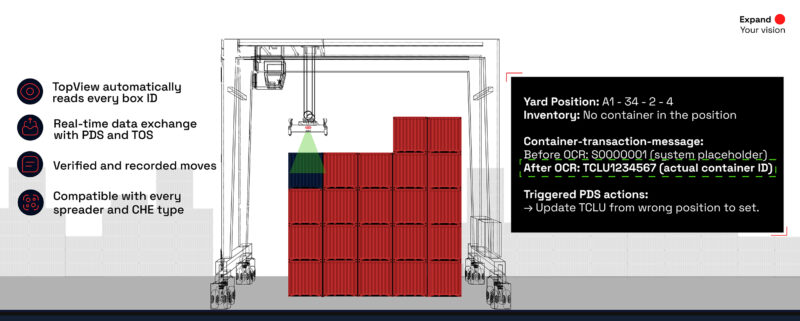

Enhancing container yard management. Visy TopView, combined with popular position detection systems (PDS), verifies box IDs on every lift. Every container movement now has an automatically digitized and validated container code based on what is actually picked rather than inventory map based on assumptions.

TopView is a spreader-mounted, AI-based OCR camera system that automatically reads the container ID on each lift. With yard cranes and lift trucks, TopView reads the box ID and immediately shares it with the PDS, which updates the TOS in real time.

It sounds simple – and in a way, it is. It is just adding visibility to containers moving from place A to place B, and the practical impact is huge: you receive confirmed container identity data on every move, shift, and day. Over time, this builds a reliable foundation for true yard visibility and inventory confidence, removing the effects of chance – whether due to technology or human error.

Container Yard Management – Where the Real Value Emerges

To better understand the benefits in terminal operations, we spoke with Ville Heinonen, TopView Product Specialist, who supports deployments and oversees product development. For over five years, Ville has been bringing TopView systems to life in North America, LATAM, APAC and Europe on all types of equipment, including RTGs, RMGs, reach stackers, and top picks.

When asked where the real value comes from, Heinonen explained: “The OCR reading is the key enabler you need to create value. However, two aspects intertwined with it are essential. First, you need to be able to trust it is the correct code – even when there can be several codes visible in the images or IDs that are damaged. Therefore, ensuring correct reading has been a significant part of product development – without it, you start to destroy the value. Second, I want to emphasize that to achieve real impact you also need the right tool, and in this case, it is system integration. That is how operations start to benefit from this improved data. And when OCR-PDS-TOS play together, you start to see the impacts.”

Three critical data points converge:

- After lift, OCR identifies the container being handled and shares it with the PDS

- After set, PDS confirms the location where the identified container landed

- TOS gets an update of the destination and container ID, keeping it up to date

“When these three systems integrate properly, you achieve automatic validation of containers with high reliability, and all the relevant parties using and requiring this information receive it immediately. They can then make corrective moves based on actual information – on the spot”, Ville notes.

Visy TopView’s OCR engine is configured with built-in logic to identify which container is being handled and ignore other visible codes.

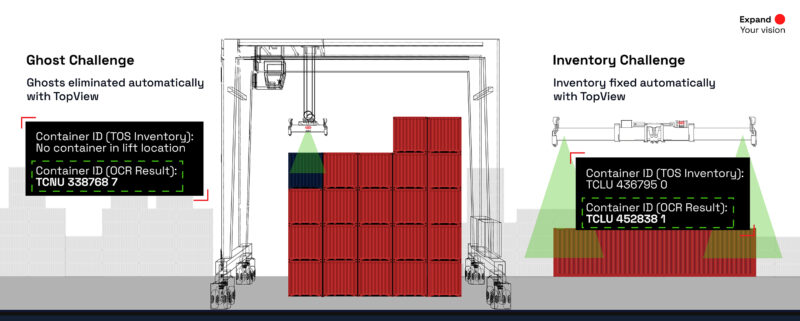

PDS adds value, but there are scenarios in the yard that lead to incorrect lifts and lost boxes. PDS alone does not have the ability to self-correct or fill in gaps. That is where OCR comes in to complement it. “And when the integrations are working, OCR brings real value when combined with PDS, by tackling the traditional issues associated with them. You get rid of picking the wrong 20ft container from a 2x20ft trailer due to GPS inaccuracies. You eliminate placeholder codes assigned to containers that shouldn’t be there, and at the same time you identify locations that either do not have a container or where the ID is wrong. The benefits are manifold, and all this information flows all the way to OPS,” Heinonen says.

TopView is CHE manufacturer- and spreader-agnostic. All equipment can be retrofitted to improve operations. “We’ve primarily equipped manual cranes with TopView, but the same benefits apply to automated cranes, where adoption is growing worldwide. With manual cranes in the yard, it essentially complements the PDS system. With automated cranes, it is even more proactive, not allowing the wrong container to be picked in the first place if it doesn’t match the job”, Heinonen adds.

Perfecting Your Yard Inventory

One of the most persistent challenges in container yard management is the issue of ghost containers:

- Containers that are in the stacks but not shown in the inventory (or located in incorrect location)

- Containers within the stacks and inventory without known IDs (identified ghosts)

Sometimes these issues can even be so widespread that the unknown codes in the system cause the stack to look like “Swiss cheese”.

Another prevalent issue is flawed inventory, such as an incorrect box ID on a container in the stacks. These errors can originate from incorrect manual entry, PDS misplacing containers due to GPS or mapping inaccuracies, emergency moves, missed moves caused by CHE issues, or a wide range of other reasons.

No matter what the cause, these errors happen in almost all terminals. And once the actual and digital yards diverge, problems compound rapidly:

- Inventory accuracy deteriorates

- Equipment productivity drops

- Operators waste time searching instead of moving containers

Without OCR automation, terminals are forced into a constant cycle of audits, physical checks, and manual corrections in time-consuming and costly attempts to fix data input errors. This game of catch-up hurts performance metrics and leads to inconsistent operations.

Visy TopView captures container IDs directly from the roof – delivering high-accuracy readings even when codes are damaged or hard to read.

Automation improves container yard management accuracy, affecting every metric that matters:

- Vessel turnaround times decrease because moves aren’t wasted searching

- Equipment utilization increases as operators focus on productive lifts

- Rehandles become far less frequent because containers are where they should be

- Labor productivity improves because staff trust the system

- Fewer claims due to lost containers

- Improved customer relationships because operators deliver what they promise

In addition to improving KPIs, accurate inventory unlocks hidden capacity. Inventory confusion is a silent constraint on throughput. Resolve it, and terminals can handle an increased volume without adding equipment or expanding yard footprint.

Container yard management with TopView – Conclusion

Visy TopView solves container yard inventory challenges by ensuring every container movement has a verified container ID captured and shared across the mission critical systems. Even if mistakes or discrepancies occur within the yard due to operational factors, the OCR system automatically corrects them later in the process when containers are handled.

Hence, together, TopView, PDS, and TOS data exchange align the actual and digital yard inventories, helping terminals achieve operational excellence – both by eliminating challenges and automatically fixing them.