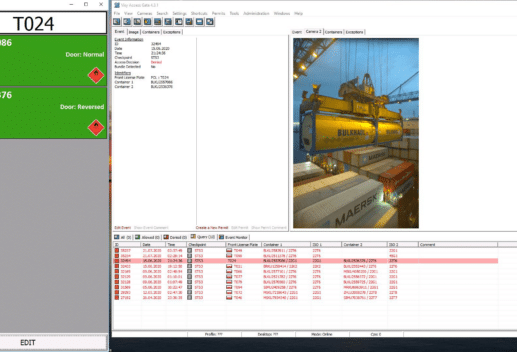

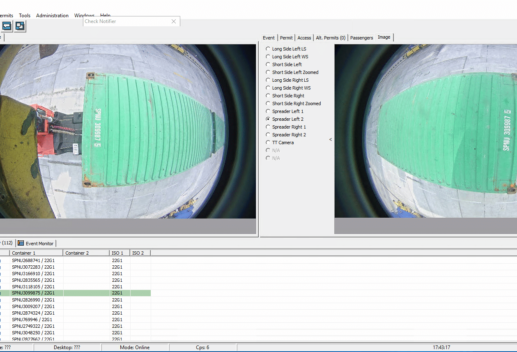

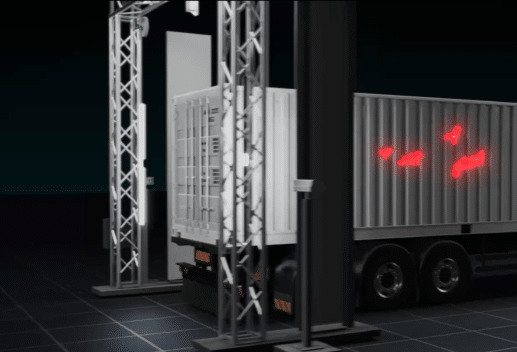

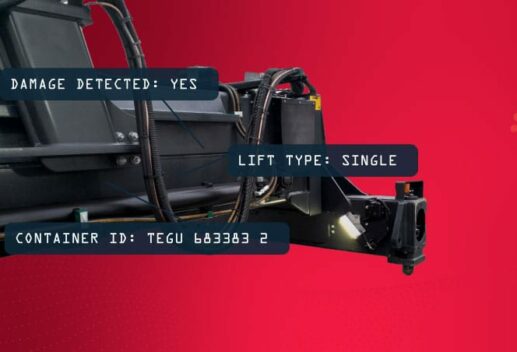

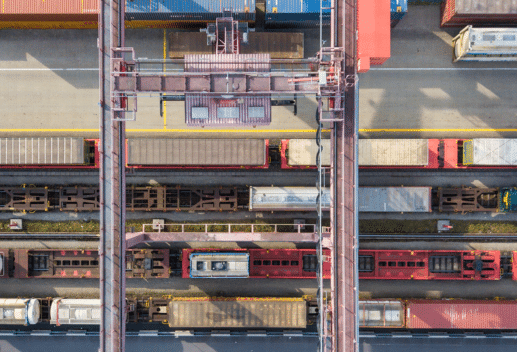

Visy Crane OCR for ship-to-shore (STS) cranes automatically images all container sides and recognizes container IDs, ISO codes, dangerous goods labels (IMDG, ADR), and other targets of interest such as seal presence and door direction, while containers are being handled by cranes.

Robust system environment with exceptional performance

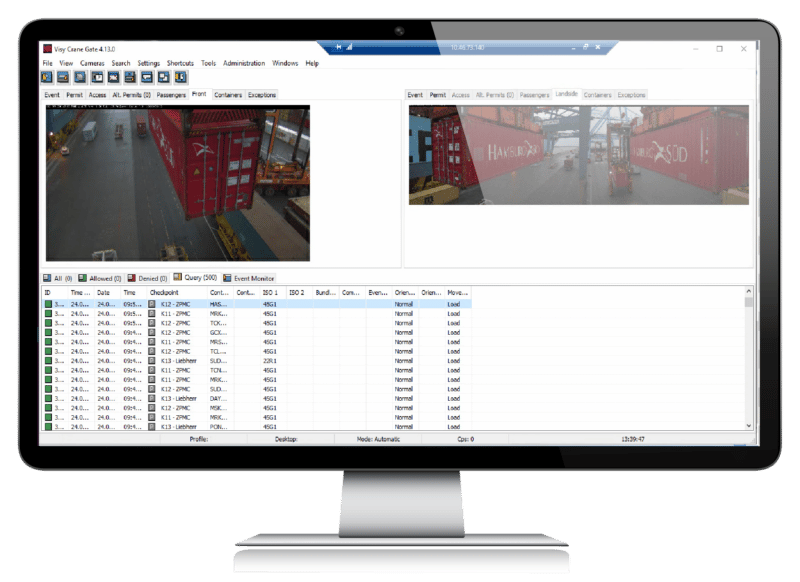

Due to harsh operating environment and multiple parallel functions, the Visy Crane OCR system setup and equipment environment utilizes PTZ (pan-tilt-zoom) cameras mounted on the portal beams and crane legs without moving parts to enhance system reliability and durability. The PTZ cameras are easily controlled to provide an optimal view for all lifting cases and interface with PLC accurately calculate flight paths to optimize the imaging moment. Visy container OCR software digitizes the required attributes of captured high-quality images and brings the data available in real-time in Visy Crane Gate application and TOS.